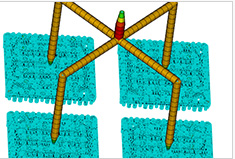

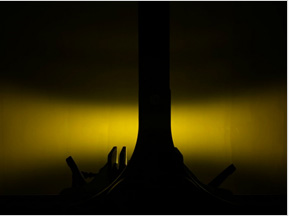

there is an exercised mold engineers to guarantee the injection producing, we will ooffer design 3D work on Solickwords or PRO/Engineer AUTO-CAD,and do the design for manufacture(DFM) and mold analysis to solute the issues may happen in producing, it will much avoid predict issue, and make the injection produce smoothly. what is more, when the LED optics are producing, our injection workshop engineers will adjust the injection machine, to keep the tolerance, the surface of the part are shiny, without black spot, burr.

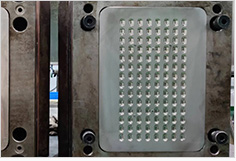

LED lens is a high-precision optical accessory, which has extremely high requirements on the accuracy of the mold. Because the tolerances are not matched, the design optics of the lens will be affected, so the production of the mold must be controlled very accurately, Brightlx provide processing of such high-precision molds: ultra-precision processing machines,PERCIECHNANOFORM350, CNC comprehensive processing machines, screen grinders, milling machines, CNC electrical discharge machines, surface contouring instruments, etc. The most accurate part of the mold is the optical part, so we only select the best grade of steel, and then use the ultra-precision processing machine to process the curved surface with aspheric technology.

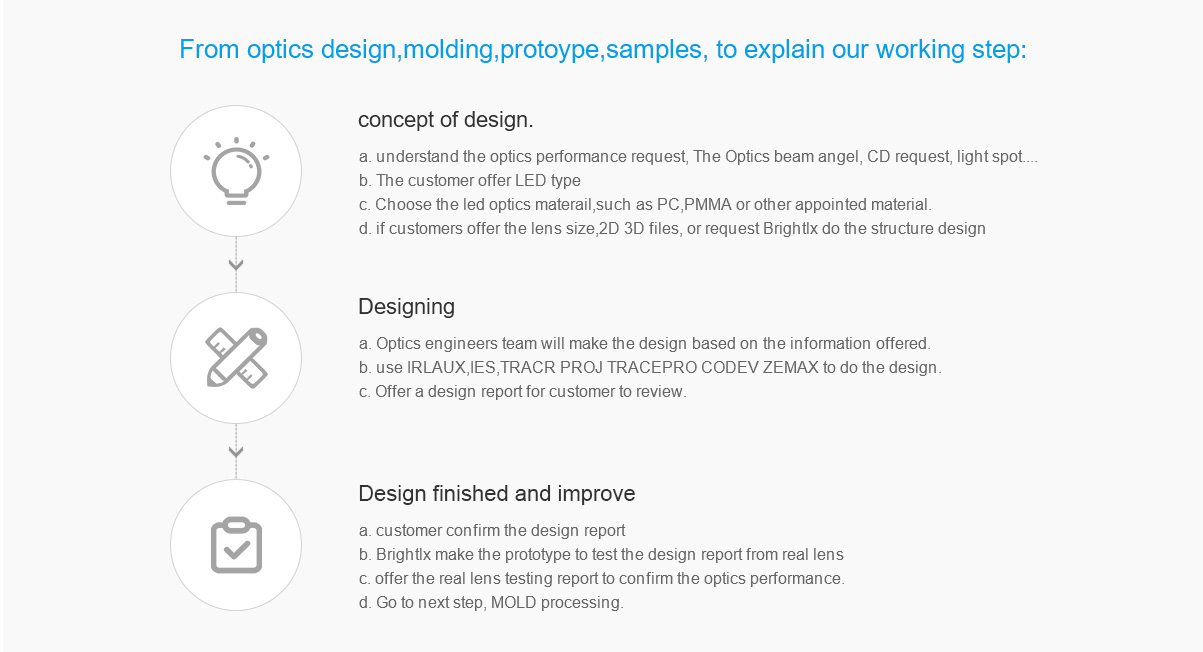

|

|

|

|

|

We know that lenses require very sophisticated equipment to produce, and different sizes require high tonnage of injection molding machines, so we have 80T, 120T, 180T, 260T, 480T and other tonnage injection molding machines, excellent equipment It is also an important factor to ensure the high quality of products, including advanced mold manufacturing, processing and testing equipment imported from Japan, Germany, and other countries. We pursue: no bubbles, no dents, no sink marks, no flow lines, no crescent.

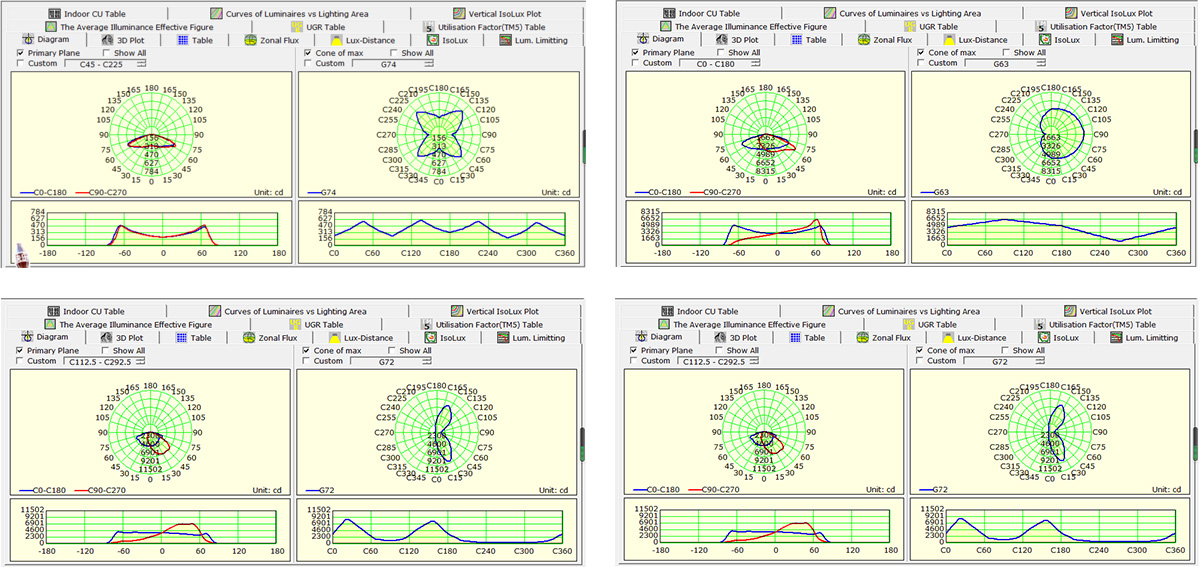

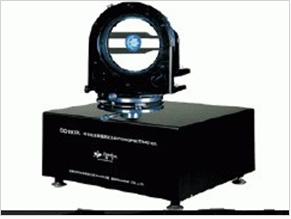

Brightlx made the design to tooling, injection and test for the lenses.we have professional optics Lab to test the optic performance of design, and samples ,Mass production ‘optics to match the project design.

|

|

|

|

Address:Shenzhen Baoan, Guangdong Province, China

Address:Shenzhen Baoan, Guangdong Province, China E-mail:sales@lensblx.com

E-mail:sales@lensblx.com Phone:0755-27190367

Phone:0755-27190367

Copyright © 2021 Brightlx Optics Website building:heyou

About Us

About Us