-

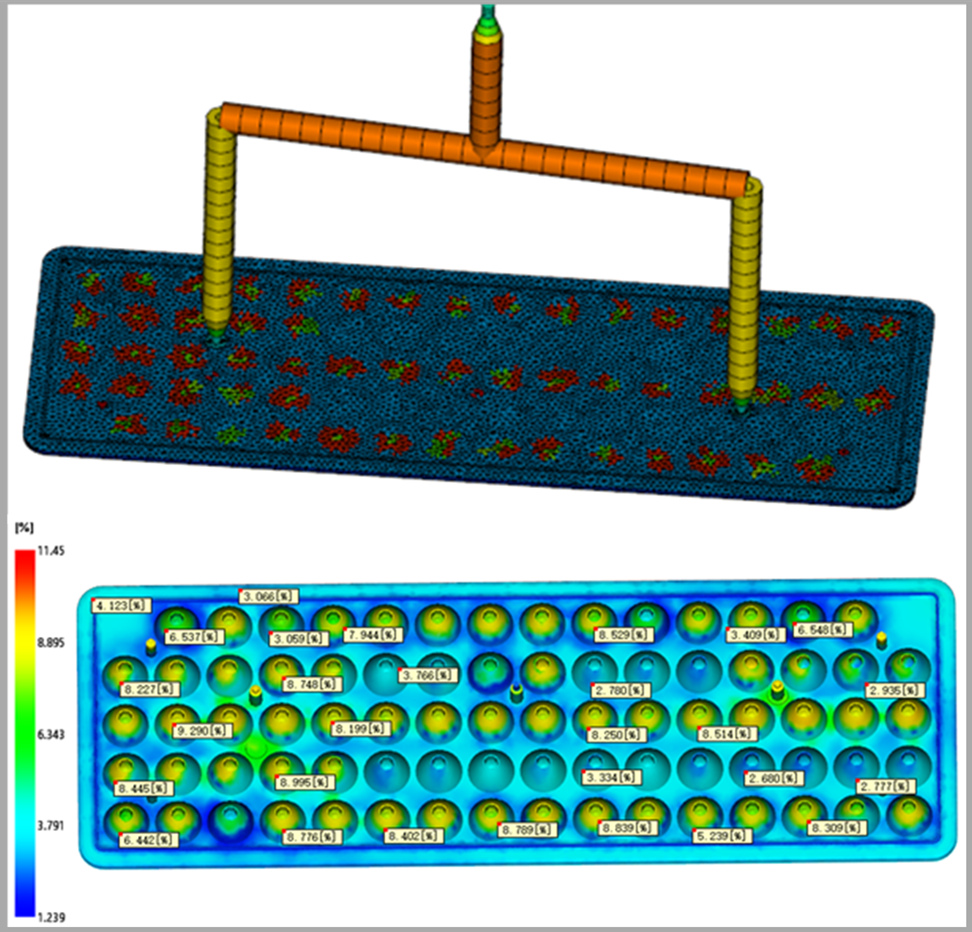

What is Mold Flow Analysis?

Mold flow analysis (MFA) software simulates the flow of plastic, which allows you to elevate part and mold design to create products of impeccable quality. MFA gives you a virtual sneak peek into how your material of choice will fill the mold’s...

2024-03-26 See More -

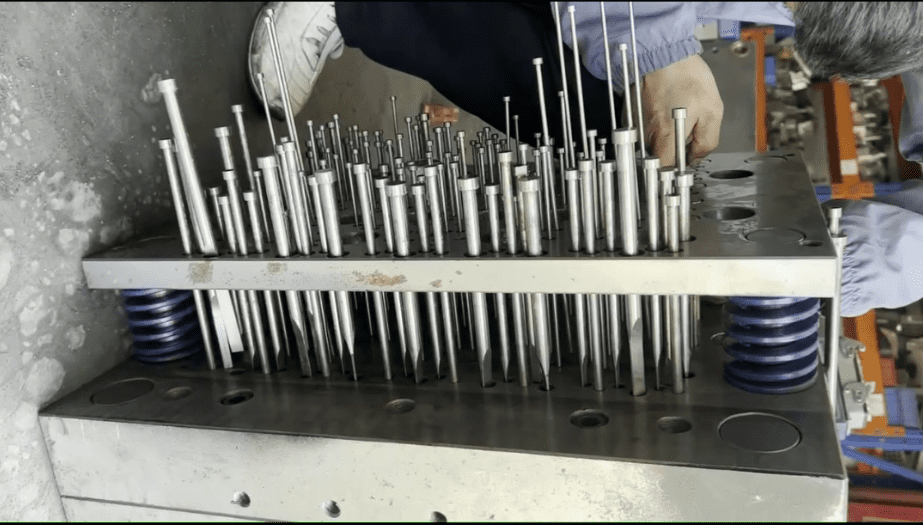

The role of ejector pins in LED lens injection molds

The ejector pin plays a crucial role in LED lens injection molding.

2024-03-14 See More

Its main functions include:

1. Sealing the injection port

when the mold is closed, seals the injection port to prevent leakage or overflow of the injec... -

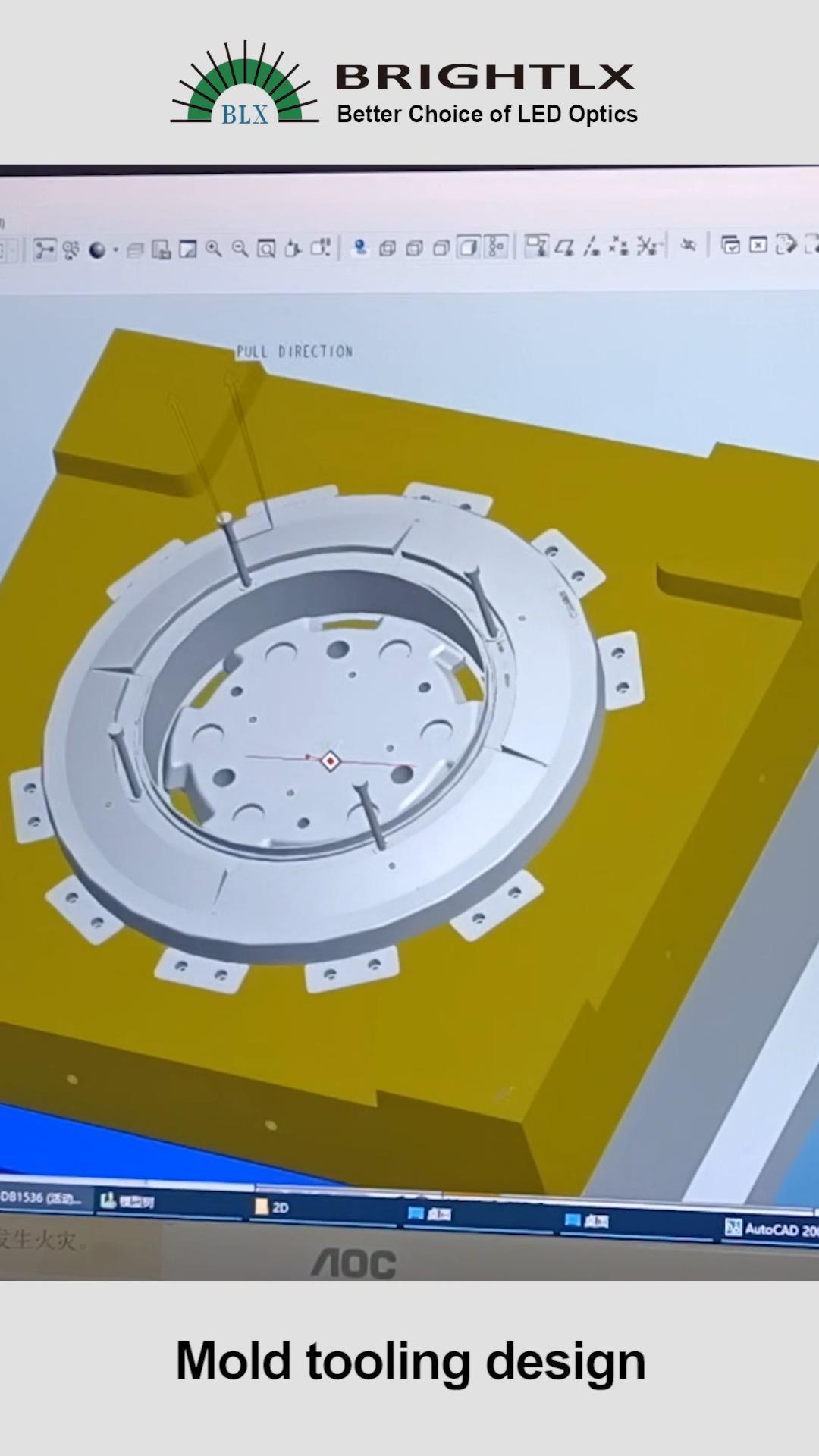

How Brightlx goes step by step from design, production, to testing?

Glad to share a video show how Brightlx goes step by step from design, production, to testing.

2024-03-06 See More

Click on the link to know more: https://www.linkedin.com/company/12890851/admin/feed/posts/

At Brightlx, we are not just a manufacturer. We... -

New 400T injection molding machine

Good news, Brightlx has a new 400T injection molding machine. We now have a total of 40 injection molding machines in our factory.

2024-03-01 See More

From 80 to 480 tonnes, we have more production advantages.

1. Wide range of production: optical parts w... -

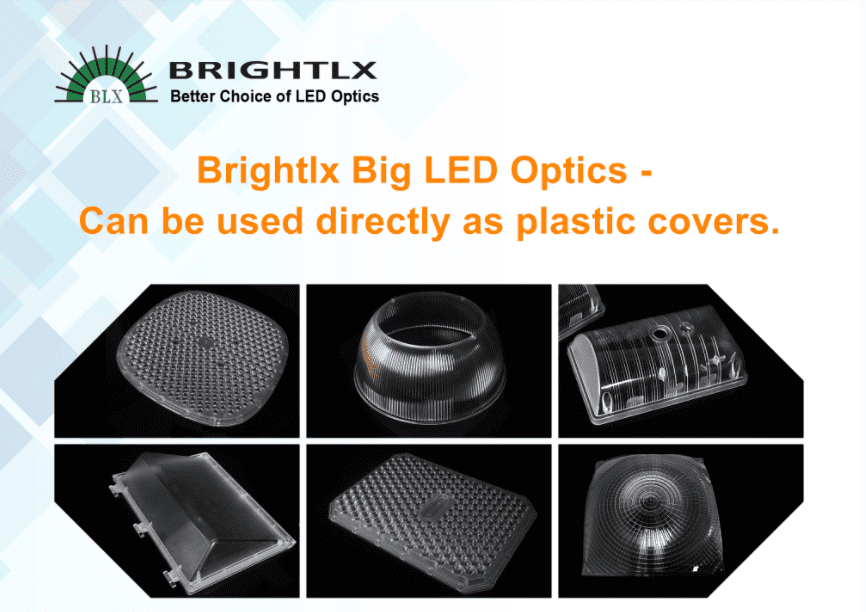

Bespoke Big LED Optics Cover

These customized large lenses can be used for canopy fixtures, wall pack lights, high bay, street lights, etc. They can be well suited to meet the scene’s requirements regarding glare, uniformity, light distribution direction, and so on.

2024-02-29 See More

<... -

Brightlx returned to work from CNY!

Brightlx has officially returned to work today. Our Team is energized and ready to support your LED OPTICS projects!

2024-02-19 See More

As a manufacturer of custom-made LED lenses, we rely on excellent optical design, high-precision mold-making, and part inj... -

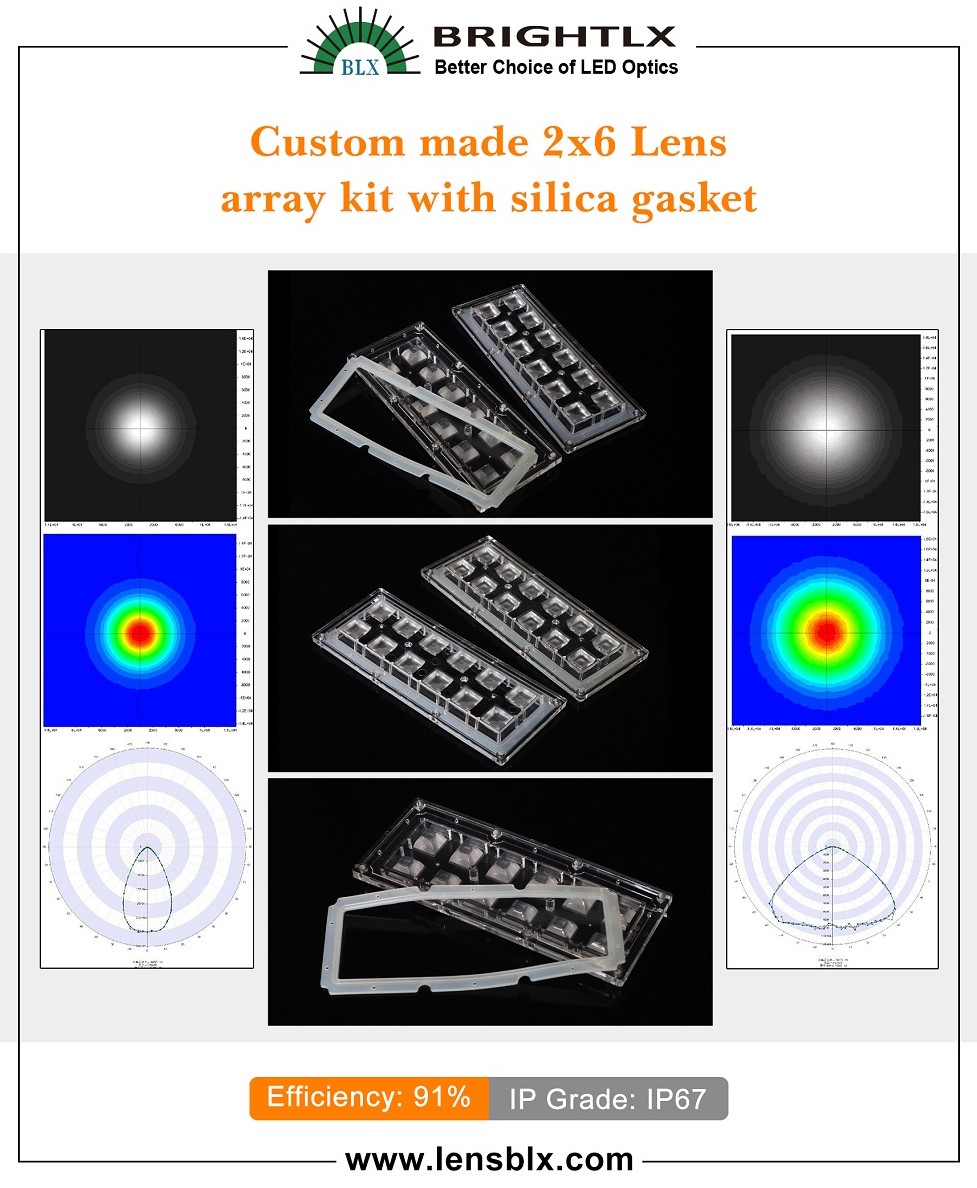

Ready to take your project to the next level with customized waterproof lenses?

Here are some customized IP67 waterproof-rated LED lens cases we have done before, the IP67 rating signifies that the LED lens is not only dust-tight but can also allow for short-term immersion under specific conditions. This level of protection ensu...

2024-01-30 See More -

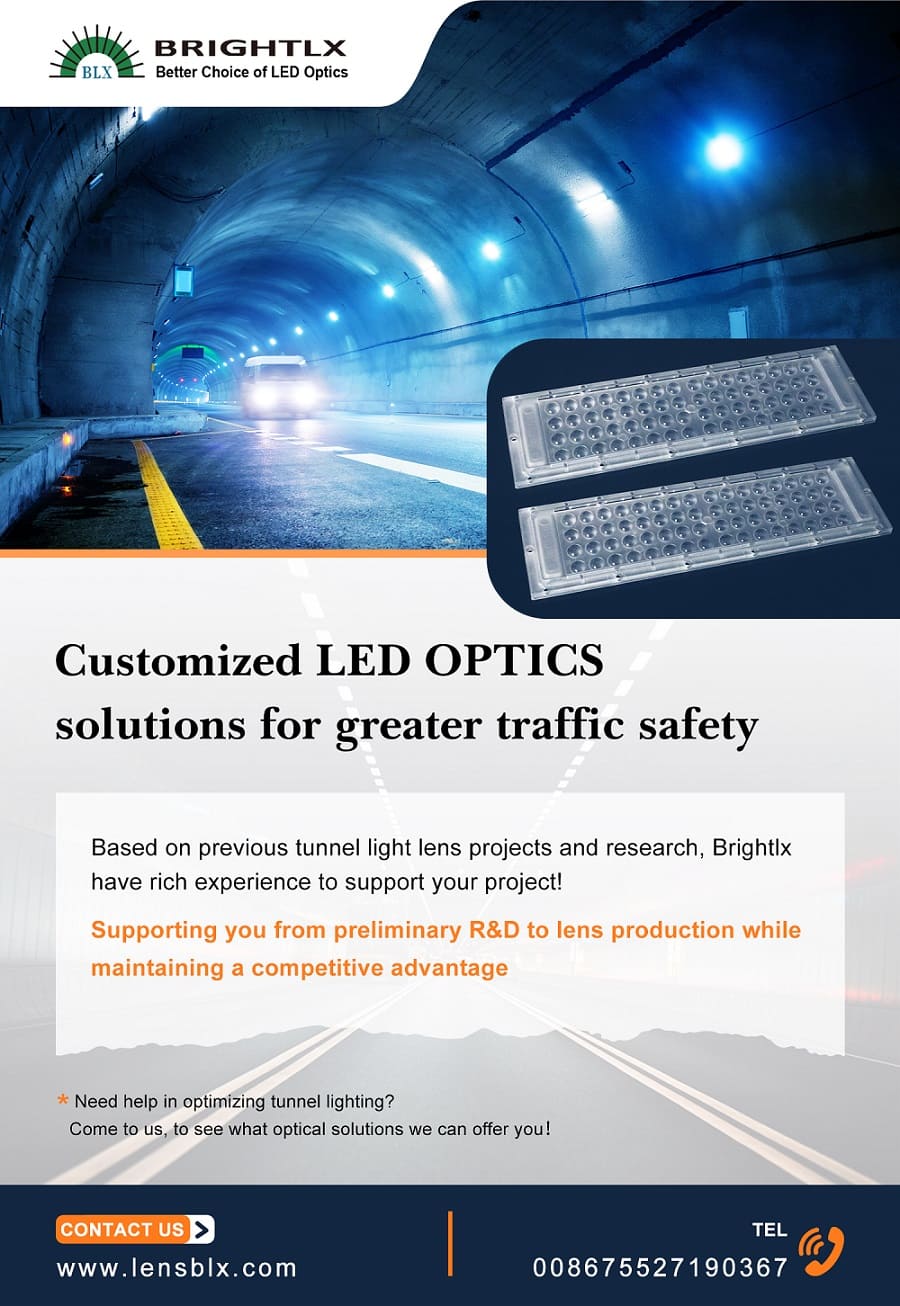

Optimized Lighting Distribution For Tunnels

High-effective tunnel and underpass lighting require consistent light levels throughout the structure for safe passage. Based on previous tunnel light lens projects and research, Brightlx have rich experience to support your project!

2024-01-25 See More

Suppo... -

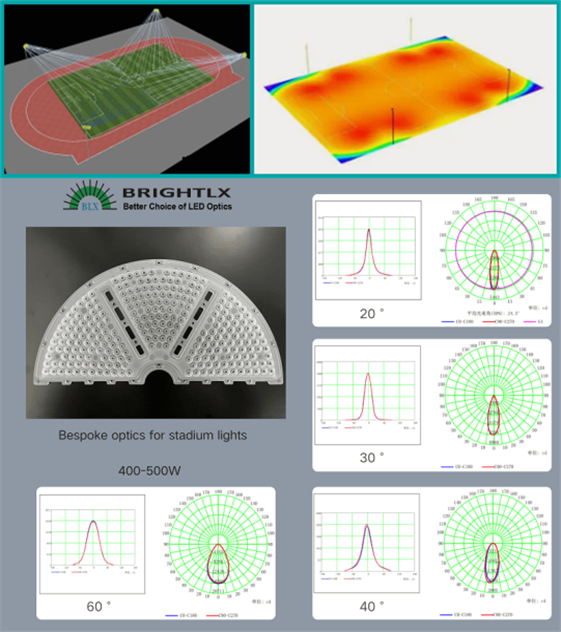

How to match different lenses for stadium lights in different locations?

As we all know, the excessive glare and overflow of stadium lighting not only affect the quality of the game, but also bring discomfort to the spectators and the surrounding environment.

2024-01-18 See More

Matching lenses for stadium lights in different loca... -

Employing diverse tonnage injection molding machines for a variety of lenses.

Hello, everyone, we are thrilled to introduce how we use diverse tonnage injection moulding machines for a variety of lenses in Brightlx Optical Limited.

2024-01-12 See More

80T Injection Molding Machine:

Ideal for small-sized lens production with limite... -

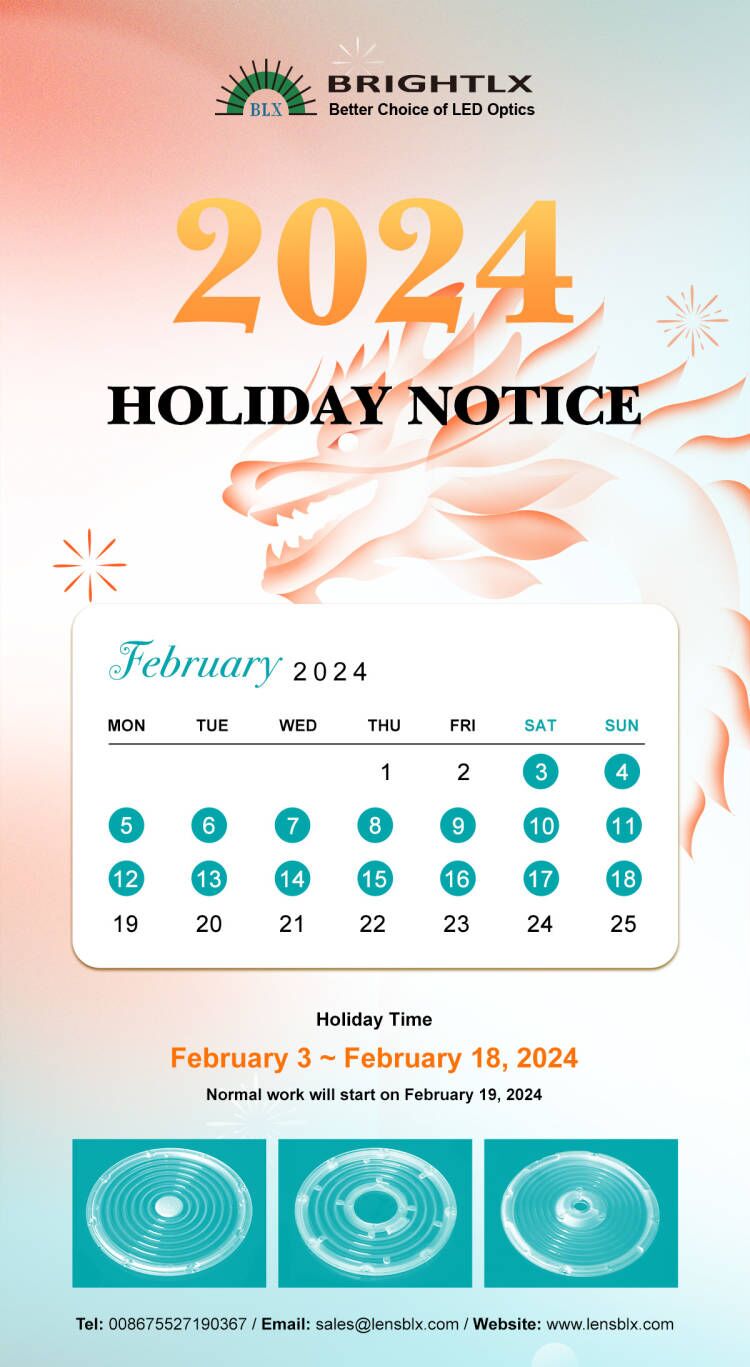

Chinese New Year’s Holiday Notice

Dear Customer,

2024-01-10 See More

As the Chinese New Year approaches, we would like to inform you of our upcoming New Year holiday schedule as follows:

Holiday time: To celebrate the New Year holiday, our company will be on holiday from February 3... -

Exploring Custom Optics Solutions?

Our experience spans all phases of product design, tooling design, plastic injection molding, plastic injection manufacturing, plastic part assembly & the use of rapid prototyped parts & molds production & other known techniques of prototyping.

2024-01-05 See More

...

Address:Shenzhen Baoan, Guangdong Province, China

Address:Shenzhen Baoan, Guangdong Province, China E-mail:sales@lensblx.com

E-mail:sales@lensblx.com Phone:0755-27190367

Phone:0755-27190367

Copyright © 2021 Brightlx Optics Website building:heyou

About Us

About Us