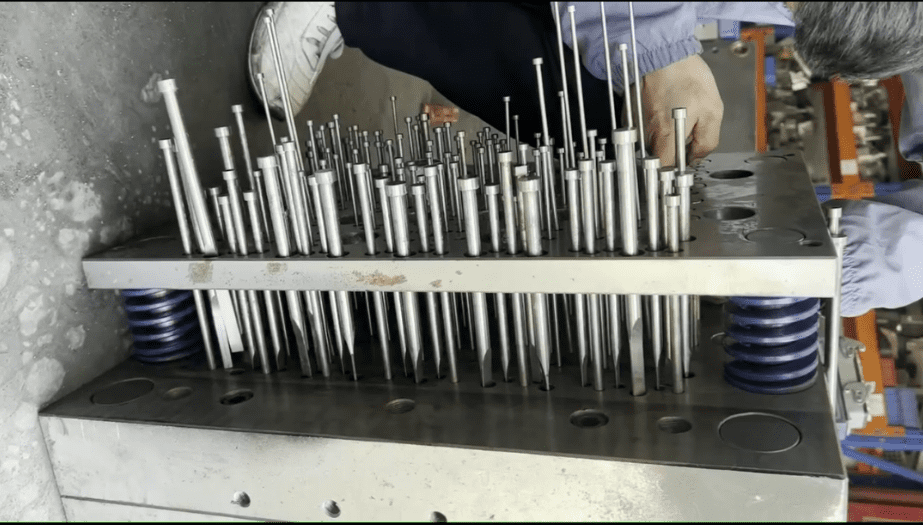

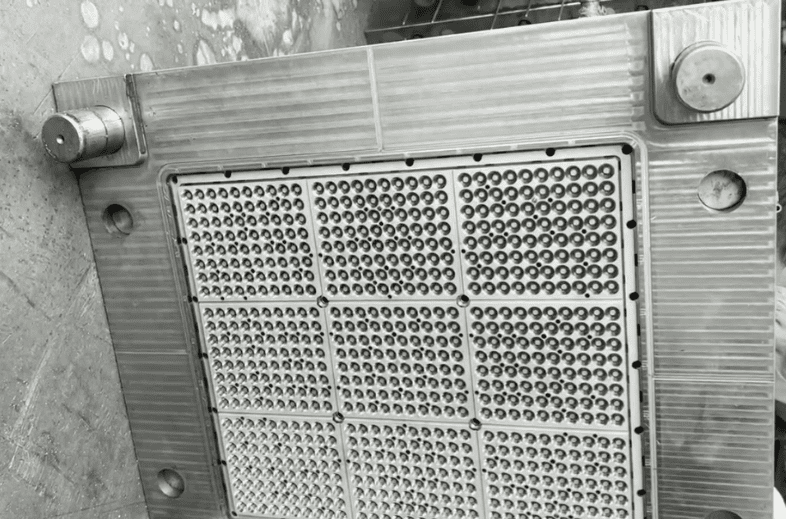

The ejector pin plays a crucial role in LED lens injection molding. Its main functions include:

1. Sealing the injection port

when the mold is closed, seals the injection port to prevent leakage or overflow of the injected material, ensuring smooth injection molding process.

2. Controlling material flow

The design and position of the ejector pin can affect the flow path and speed of the injected material in the mold cavity. Proper ejector pin design helps control material filling and distribution, ensuring the quality and consistency of molded parts.

3. Preventing gas and impurities from entering

The sealing function of the ejector pin helps prevent external air, dust, or other impurities from entering the mold cavity, avoiding adverse effects on the quality of molded parts.

4. Aiding in the release of the finished lens from the mold cavity

In some cases, particularly with complex lens shapes or intricate mold designs, the ejector pin may be used to help release the lens from the mold cavity by applying a slight force to dislodge it. This ensures that the lens is fully ejected from the mold without sticking or deformation.

Brightlx is an LED lens OEM&ODM factory, our team has extensive experience in mold tooling design and customized lens manufacturing. We can tailor LED OPTICS to meet your specific needs. Please feel free to reach out to us at sales@lensblx.com

Here is a video showing how to install the ejector pins, click to know more: https://www.linkedin.com/feed/update/urn:li:activity:7173879488399699968/

Address:Shenzhen Baoan, Guangdong Province, China

Address:Shenzhen Baoan, Guangdong Province, China E-mail:sales@lensblx.com

E-mail:sales@lensblx.com Phone:0755-27190367

Phone:0755-27190367

Copyright © 2021 Brightlx Optics Website building:heyou

About Us

About Us